The Future of Style: Exploring DTF Printing Modern Technology in the Fabric Market

In recent times, the textile sector has actually observed a marked change towards innovative innovations that are improving the landscape of style production. Amongst these innovations, Direct to Movie (DTF) printing innovation has become a promising challenger, offering one-of-a-kind capacities and opportunities for designers and manufacturers alike. This cutting-edge printing method has actually sparked rate of interest because of its prospective to transform typical fabric printing procedures. As we explore the implications and possibilities of DTF modern technology in the realm of fashion, it ends up being evident that its combination can redefine market standards and pave the way for a new age of innovative expression and effectiveness.

Evolution of Fabric Printing

From the old human beings utilizing methods like block printing to the digital transformation of today, fabric printing has actually constantly pressed boundaries. As the craft spread to other parts of the globe, brand-new approaches such as screen printing and roller printing arised during the Industrial Transformation, changing the textile industry.

The intro of digital textile printing in the late 20th century marked a considerable change towards more sustainable and versatile printing techniques. The development of textile printing showcases a rich background of creative thinking, resourcefulness, and technological progress in the world of style and style.

Benefits of DTF Technology

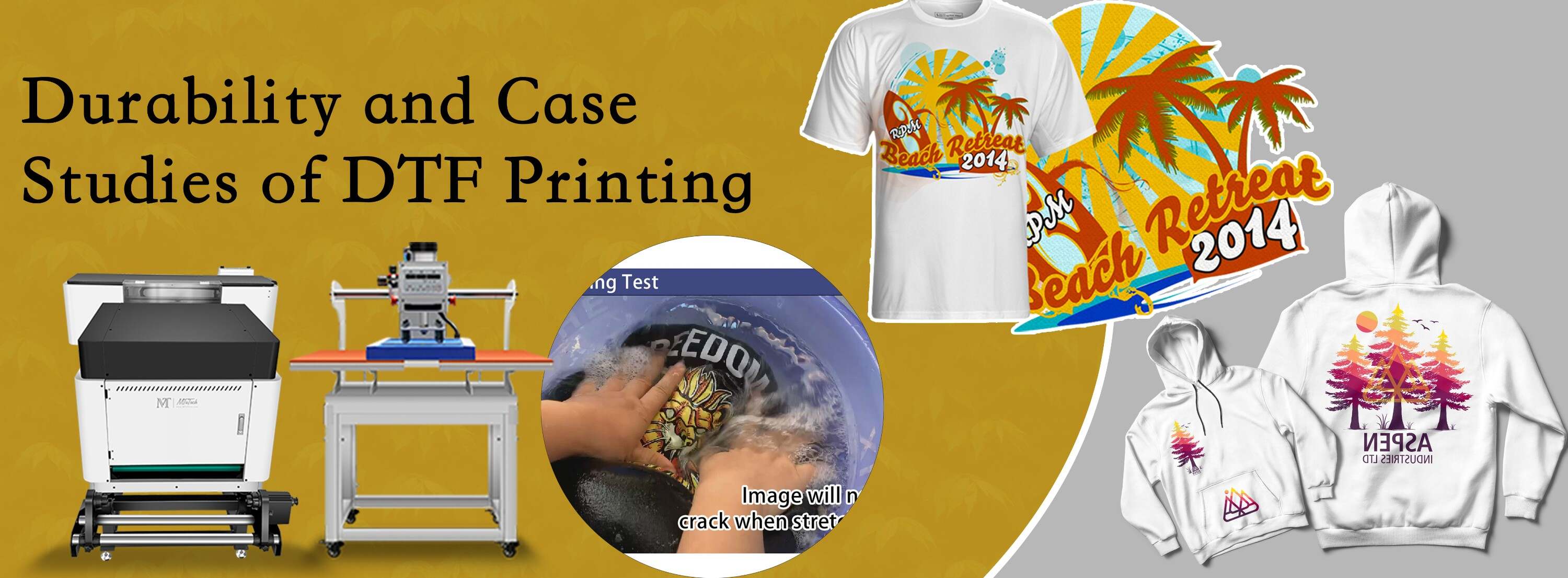

With the evolution of fabric printing techniques from old techniques like block printing to modern-day innovations such as digital printing, the intro of Direct-to-Fabric (DTF) technology has actually considerably boosted the effectiveness and sustainability of fabric printing processes. Among the main advantages of DTF modern technology is its ability to straight publish styles onto fabric without the need for transfer papers, which minimizes waste and simplifies the manufacturing procedure. In addition, DTF printing permits higher color vibrancy and information accuracy compared to conventional techniques, allowing fabric manufacturers to create intricate and top notch styles easily.

Moreover, DTF technology is recognized for its versatility, as it can be utilized on different kinds of materials, consisting of all-natural fibers like cotton, silk, and wool, as well as synthetic products such as polyester and nylon (DTF Printing). This flexibility opens up a vast array of opportunities for designers and suppliers to explore different structures and products, leading to even more one-of-a-kind and cutting-edge items in the fashion market. Overall, the implementation of DTF technology represents a substantial improvement in textile printing, supplying countless advantages that contribute to the future sustainability and creative thinking of the industry

Sustainability in Style Production

Stressing environment-friendly methods is vital in modern fashion manufacturing, straightening with the growing consumer need for sustainable products. In recent times, the fashion business has actually faced raising analysis because of its significant ecological effect, consisting of excessive water usage, chemical contamination, and fabric waste. As a response, several fashion brands are currently incorporating sustainable practices into their production processes to lessen injury to the atmosphere.

Sustainability in vogue manufacturing encompasses different facets, such as making use of recycled and organic materials, decreasing energy consumption, implementing ethical labor techniques, and advertising openness throughout the supply chain. Furthermore, improvements in innovation, like DTF printing, offer opportunities to better improve sustainability in fabric production. This innovation makes it possible for precise printing on fabrics, lowering ink wastage and water use contrasted to standard printing techniques.

Layout Flexibility and Customization

Additionally, DTF printing facilitates personalization on a scale previously unattainable, permitting for personalized garments and unique pieces customized to individual preferences. Generally, DTF printing technology transforms the layout landscape in the textile market, supplying endless possibilities for innovative expression and tailored fashion.

Effect On Supply Chain & Market Trends

DTF printing modern technology in the fabric market is reshaping supply chain dynamics and affecting market patterns with its efficiency and customization capacities. By enabling on-demand printing and eliminating the demand for big stocks, DTF technology simplifies the supply chain procedure.

Additionally, the customization possibility of DTF printing modern technology is reinventing the their explanation market fads in the fabric industry. Customers progressively seek one-of-a-kind and individualized items, and DTF allows brand names to provide custom styles cost-effectively. This customization ability not only boosts customer satisfaction yet also opens new possibilities for companies to provide to specific niche markets and separate themselves from competitors. As an outcome, DTF innovation is driving a change towards even more cutting-edge and customer-centric approaches within the fabric industry, shaping the future of style.

Final Thought

In conclusion, DTF printing innovation is reinventing the fabric industry by providing countless advantages such as design sustainability, flexibility, and customization. This innovative technology is reshaping the future of fashion production, affecting supply chains, and driving market trends towards more environmentally friendly and effective practices. As the market remains to develop, DTF printing will play a critical duty in forming the means fabrics are generated and eaten in the years ahead.

From the old human beings making use of strategies like block printing to the electronic transformation of today, textile printing has continually pushed borders. As the craft spread to various other components of the world, new methods such as display printing and roller printing arised during the Industrial Revolution, revolutionizing the textile sector.

The intro of digital textile printing in the late 20th century noted a considerable shift towards even more versatile and lasting printing techniques.With the development of textile printing strategies from ancient Look At This methods like block printing to modern-day advancements such as digital printing, the introduction of Direct-to-Fabric (DTF) modern technology has significantly boosted the effectiveness and sustainability of textile printing procedures (DTF Printing).In action to the vital shift in the direction of sustainability in fashion manufacturing, the adoption of innovative modern technologies like DTF printing not only addresses ecological issues but additionally opens up avenues for unmatched style freedom and personalization in the textile market